in which you can trust

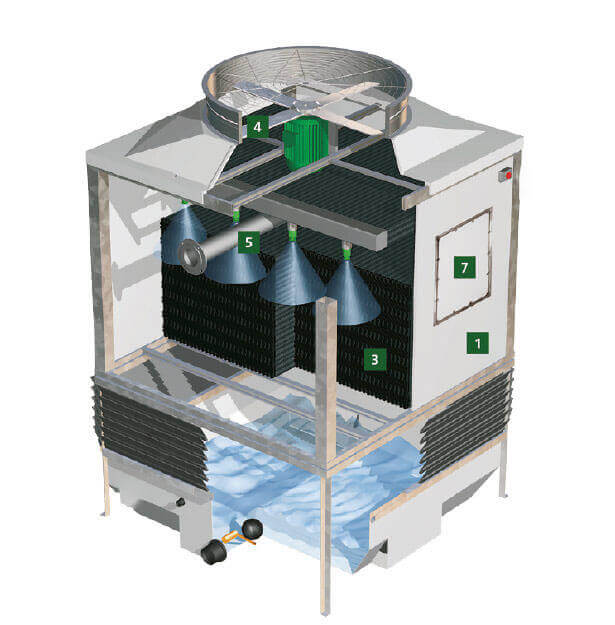

PME E cooling tower with open circuit

PME Series

Potential power from 580 to 2600 kW

Single and dual-cell cooling towers with axial ventilators, suitable for container transport.

The body is made from fibre-glass modular sandwich panels, joined together by means of a steel structure that is hot-dip galvanised after assembly; the screws used are made from AISI 304 steel; the collection trough (optional) is made from glass-fibre-reinforced polyester resin.

The tower packing inserts for the heat exchange and the mist eliminator are made from PVC, as are the water distributor, the drainage nozzles and the overflow pipe. The full-cone nozzles are made from polypropylene and are clog-free. The splash guard screens are made from glass-fibre-reinforced polyester resin by means of an extrusion process.

There are 16 models available with a potential power of approx. 580 to 2600 kW (power as a guideline with temperature drops of 5 °C).

The use of plastic results in a low weight and means that the plant can be installed anywhere.

Directly coupled axial ventilator system, low energy consumption, low noise level

Body and trough made entirely from fibre-glass, corrosion-free

PVC distribution system with clog-free polypropylene nozzles with large openings

Tower packing with large opening (20 mm profile), suitable for use with industrial water

Manhole or detachable side wall

Protective grille and screws in stainless steel

Outer shell

(body, nozzle cap and trough optional) made entirely from glass-fibre-reinforced polyester resin, self-supporting structure with exclusive design and UV-protective Gelcoat coating.

Splash guard screen

made from glass-fibre-reinforced polyester resin (only in the version with the trough).

Inspection window

Round with a polyamide body and a polycarbonate window, which can be easily opened for an inspection of the inside of the cooling tower.

Tower packing

(cooling or heat exchange sheets) are made from self-extinguishing, decay-resistant PVC sheets, thermoformed under vacuum and then glued together. This tower packing is of the optimal form, composition and dimensions for contact with air/water inside the tower and for the corresponding heat exchange.

Mist eliminators

are made from self-extinguishing, decay-resistant PVC sheets, thermoformed under vacuum and then glued together. The form and dimensions of the sheets are designed as such that the transference of water droplets via the ventilator flow is kept to a minimum.

Supporting structure

for the tower packing and mist eliminator (if present) in hot-dip galvanised steel.

Water distribution system

with standardised pipes and PN 10 connections in PVC, consisting of a main collector with one or more threaded connections for the attachment of spray nozzles. The system is designed in such a way that the even and homogeneous distribution of the water to be cooled to the tower packing is guaranteed.